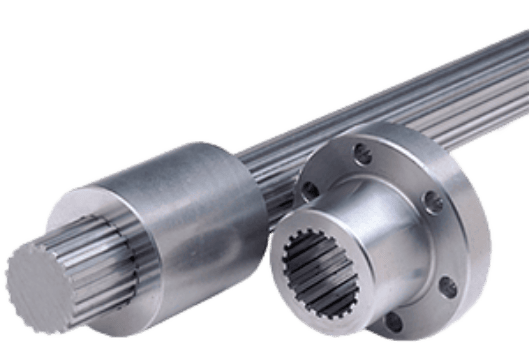

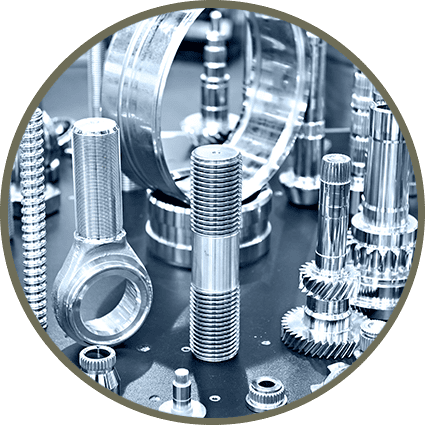

Grob Inc. supplies a variety of cold formed products, including spline shafts, standard and custom timing belt pulleys, flanged bushings, broached sleeves, heat exchanger tubes and drums, and spur gears.We engineer excellence into every cold formed product, delivering stronger and more economical parts to end users. Learn more about the Grob Cold Rolling method, our cold formed products, the benefits of our cold forming process, and the custom machining services we offer.