Standard Spline Shafts

Standard Spline Shafts

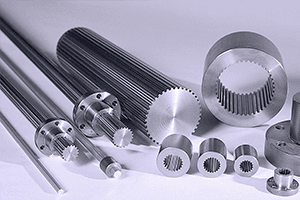

Grob Standard Spline Shafting has been designed to maximize torsional strength and contact area. Grob’s cold formed spline shafts are made with an even number of teeth and are parallel over two or more teeth. When your project requires mating parts, look no further.

For your convenience we have off the shelf mating broached sleeves and flanged bushings to match our Grob Standard Spline shafts. We also offer custom broaching of your parts to match with our Grob Standard Splines.

- Full Flank Fit

- Large Contact Area

- Equal size tooth to space ratio

- The same pressure angle as parallel sided spline

- 3 x’s the work surface of parallel sided spline

- Mating sleeves or flanged bushings

Specifications

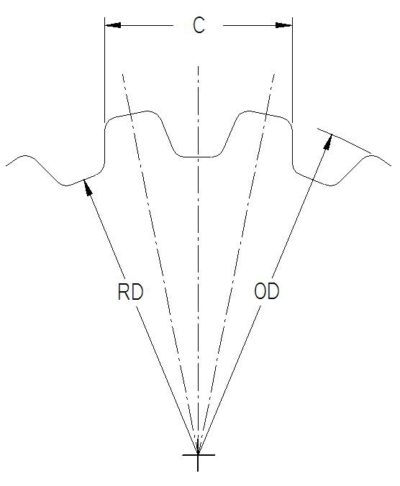

| Grob Spline # | OD (Outside Diameter) Min-Max | RD (Root Diameter) Min-Max | Chord Measurement (C) | OD/Root Radius | Specs & CAD Link |

|---|---|---|---|---|---|

| 0250-20-2 | .263 – .265 | .233 – .235 | .057 – .058 | .004 – .006 | View Specs & CAD |

| 0344-16-2 | .376 – .379 | .308 – .311 | .098 – .099 | .006 – .010 | View Specs & CAD |

| 0406-16-2 | .434 – .437 | .372 – .376 | .117 – .118 | .005 – .008 | View Specs & CAD |

| 0468-16-2 | .502 – .505 | .424 – .428 | .136 – .137 | .008 – .012 | View Specs & CAD |

| 0500-16-2 | .534 – .538 | .458 – .462 | .144 – .145 | .007 – .010 | View Specs & CAD |

| 0562-16-2 | .597 – .602 | .518 – .523 | .162 – .163 | .007 – .010 | View Specs & CAD |

| 0595-20-2 | .626 – .631 | .554 – .559 | .138 – .139 | .007 – .010 | View Specs & CAD |

| 0625-16-2 | .671 – .675 | .574 – .578 | .180 – .181 | .008 – .011 | View Specs & CAD |

| 0687-16-2 | .736 – .740 | .632 – .636 | .199 – .200 | .008 – .011 | View Specs & CAD |

| 0710-20-2 | .747 – .751 | .666 – .670 | .165 – .166 | .008 – .011 | View Specs & CAD |

| 0750-16-2 | .802 – .807 | .690 – .695 | .217 – .218 | .009 – .012 | View Specs & CAD |

| 0875-20-2 | .925 – .930 | .820 – .825 | .204 – .205 | .010 – .013 | View Specs & CAD |

| 0950-20-2 | 1.002 – 1.007 | .888 – .893 | .221 – .222 | .011 – .014 | View Specs & CAD |

| 1000-16-2 | 1.070 – 1.075 | .921 – .926 | .289 – .290 | .012 – .015 | View Specs & CAD |

| 1062-20-2 | 1.123 – 1.128 | .995 – 1.000 | .247 – .248 | .012 – .015 | View Specs & CAD |

| 1125-20-2 | 1.182 – 1.187 | 1.060 – 1.065 | .262 – .263 | .012 – .015 | View Specs & CAD |

| 1187-20-2 | 1.255 – 1.260 | 1.113 – 1.118 | .277 – .278 | .012 – .015 | View Specs & CAD |

| 1312-20-2 | 1.375 – 1.380 | 1.240 – 1.245 | .305 – .306 | .015 – .020 | View Specs & CAD |

| 1437-20-2 | 1.520 – 1.525 | 1.348 – 1.353 | .335 – .336 | .015 – .020 | View Specs & CAD |

| 1687-20-2 | 1.785 – 1.790 | 1.562 – 1.567 | .394 – .395 | .015 – .020 | View Specs & CAD |

| 1875-20-2 | 1.973 – 1.978 | 1.757 – 1.762 | .437 – .438 | .015 – .020 | View Specs & CAD |

| 2125-20-2 | 2.250 – 2.255 | 1.995 – 2.000 | .495 – .496 | .020 – .025 | View Specs & CAD |

| 2250-24-2 | 2.357 – 2.362 | 2.133 – 2.138 | .439 – .440 | .020 – .025 | View Specs & CAD |

| 2375-24-2 | 2.490 – 2.495 | 2.250 – 2.255 | .463 – .464 | .020 – .025 | View Specs & CAD |

| 2500-24-2 | 2.622 – 2.628 | 2.372 – 2.378 | .487 – .488 | .020 – .025 | View Specs & CAD |

| 2625-30M-4 | 2.690 – 2.695 | 2.573 – 2.578 | .919 – .920 | .020 – .025 | View Specs & CAD |

| 2875-30-3 | 2.985 – 2.990 | 2.755 – 2.760 | .744 – .745 | .020 – .025 | View Specs & CAD |

| 3625-36-4 | 3.747 – 3.752 | 3.500 – 3.505 | 1.0855 – 1.0875 | .020 – .025 | View Specs & CAD |

| 4000-40-4 | 4.115 – 4.120 | 3.875 – 3.880 | 1.084 – 1.086 | .020 – .025 | View Specs & CAD |

Request Spline Shaft Quote Online – How To

When requesting a quote for cold-formed spline shafts from Grob Inc., please include as much of the following as possible:

- Spline Number

- don’t see a standard spline that fits your need? We do custom spline shafts as well!

- Material

- All Grob Standard Splines are stocked in 1117 mild steel, but other materials are available

- If you need a specific material, or would like to discuss with a Grob rep – just let us know!

- Length

- All Grob Standard Splines are sold by the foot

- List the lengths & number of pieces you require in your request

Example:

- Spline number: 0500-16-2

- (specifications for each standard spline can be found in the table above)

- this example is a nominal .500″ spline, with 16 teeth, and the chord measured over 2 teeth

- Material: 1117 mild steel

- Length & #: 2 pieces; 3ft each

- Order: 2x, 3ft, 0500-16-2-1117

Placing all of this information in your quote request, which can be simplified: 2x, 3ft, 0500-16-2-1117 will ensure that our team can get you the most accurate quote as quickly as possible.